MAGNA Glaskeramik

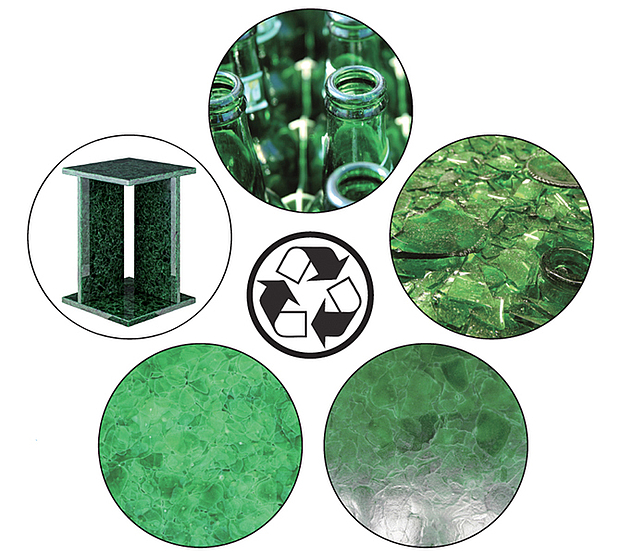

Made from 100% recycled waste and fully recyclable back into the glass production cycle after use

MAGNA Glaskeramik represents one of the latest innovations for the construction industry, architecture and design. The use of this material convinces with creative freedom and functionality.

The main advantage of using MAGNA Glaskeramik is not only the invaluable contribution to the support of the environment. The designer chooses a unique, exclusive and durable material produced under German quality standards.

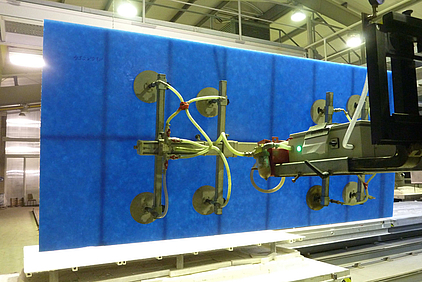

We offer raw panels - with a maximum dimension of 2800 x 1250 mm (up to 3500 x 1500 mm on request) and a standard thickness of 20 mm (15-40 mm available on request) - as well as specially cut panels for any type of object, be it interior design or facade.

Thanks to our innovative technology we have a know-how including own resources to cover any kind of request in any project phase. We are also happy to support you with technical advice.

Production

Glass waste as a source of raw materials

In the production of flat, solar, colored or bottle glass, rejects, faulty production and excess quantities of approx. 5% of the total glass production are constantly produced. This industrial waste represents our raw material source for the production of MAGNA Glaskeramik. The glass waste is first broken into shards in a controlled manner and then undergoes a complex sintering process without the addition of binders or the use of pressure, using only temperature and time. The sintered sheets are then cooled in a defined manner in cooling hoods. Finally, in the finishing department, the raw plates are calibrated, polished if desired, and cut to final size. As a result, each glass ceramic plate is unique with unique details. The resulting translucent properties, which come into their own when backlit, make the product particularly attractive.

Certified sustainability

Environmentally friendly material - environmentally conscious production process

MAGNA Glaskeramik is not only an environmentally friendly material, but also follows an environmentally conscious production process in which a large part of the energy requirement is generated from its own solar plant and the water used in the manufacturing process is also recycled and reused several times. This is evidenced by EPD certification and Cradle to Cradle certificates, which provide points in LEED or DGNB certified buildings. Thus, MAGNA Glaskeramik makes a significant contribution to the conservation of natural resources, especially in sustainable building projects. This is a factor that should not be underestimated with regard to ecological requirements.

Quality management

Made in Germany

MAGNA Glaskeramik is produced Made in Germany at our plant in Teutschenthal.

Process stability and reliability are decisive factors in the technically demanding manufacture of our unique products. Our innovative technological know-how in combination with comprehensive quality management forms the basis of our claim to always supply our customers with high-quality products.